Recently Viewed

|

|

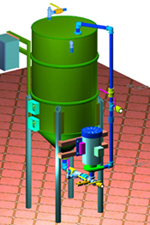

MM63 Gallon Biodiesel Processor Plans

|

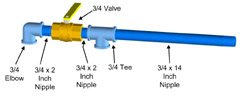

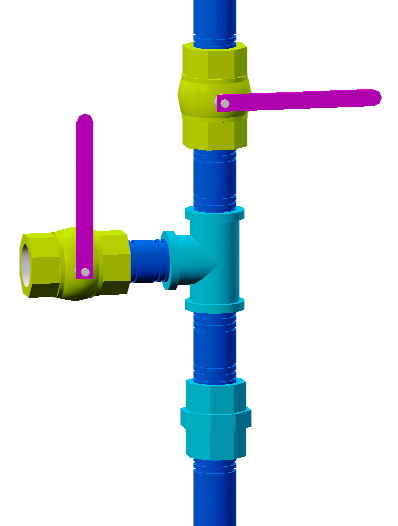

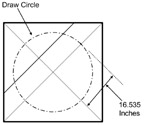

You get over 110 pages filled with detailed drawings and pipe-by-pipe instructions describing each step of the construction process for each component of the Biodiesel Processing System.

This isn’t just a Biodiesel Reactor, although you could build just that part if you wanted, these plans describe how to make an entire Biodiesel Processing System that will allow you to produce ASTM Grade high quality fuel. |

|

A complete materials list

|

|

|

Step by step directions for assembly complete with:

|

|

|

Supplimentary Information:

|

|

|

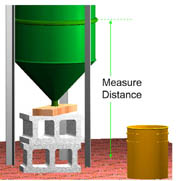

The 3D computer generated graphics explaining each step of the construction process are amazing!

Bonus Material:

- How to make a simple $10 tool for bending the cone and making it look good!

- All about titration supplies!

(This section alone will save you the money you paid for these plans)

- World class technical support from Murphy's Machines!